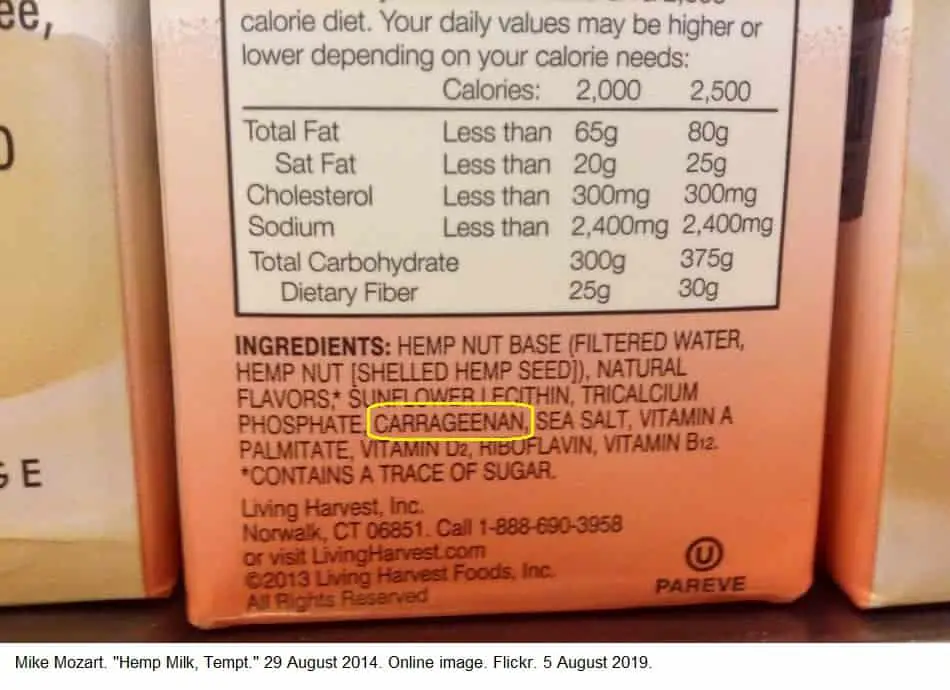

Carrageenans are a family of polysaccharides (a fancy word for complex carbs) that have several uses in the food industry including thickening, gelling, and stabilization. Folks encounter the ingredient all the time when scanning food labels for vegan-friendliness, and want to know if the ingredient is cruelty-free.

Is it vegan? Yes, carrageenan is 100% vegan-friendly. It’s simply a linear sulfated carbohydrate extracted from red edible seaweeds.1 However, the ingredient is used in the manufacturing of several non-vegan food applications.

What we’ll do here is go over the use of carrageenan in both vegan and non-vegan foods.

Carrageenan in Vegan Foods

Emulsification and Stabilization

Reduced-Fat Food Products

Vegetable gums like carrageenan are usually sold as a dry powder to be used as a stabilizer in the production of certain low-calorie whipped topping, puddings, confections, ice creams, and dressings.

Vegan Ice Creams

Carrageenan is used in many frozen products because vegetable gums help control crystal growth, and allow the food to remain stable in the freezing and thawing processes.2

Carrageenan is considered a hydrocolloid food additive, which is a class of additives that contain several hydroxyl groups, making them hydrophilic—meaning they love to attract water.3

The ability of hydrocolloids to bind water stabilizes products during the freezing and thawing process.

Bread Products

Fibrous compounds in plants that gel up when exposed to water do so because they have a unique ability to absorb water and swell up to a size several times their original volume.

This allows the additive to be used to increase the moisture content and volume of bread products.

Specific types of hydrocolloids that tend to be used in breads include carboxymethyl cellulose (CMC) aka cellulose gum and guar gum. I wrote articles on cellulose gum and guar gum and their vegan status you may want to check out.

Kappa-carrageenan is another gum used in bread products. It improves dough stability during the proofing process.4

Kappa-carrageenan also positively affects the process of gelatinization as well as the pasting properties of wheat flour.4

Vegan-Friendly Emulsions (Salad Dressings, Etc.)

Emulsifying agents like carrageenan act as a bridge between water and oil compounds, which don’t normally like to mix.

Carrageenan is a two-part molecule, with one portion being hydrophobic (water-fearing) and the other portion being hydrophilic (water-loving).

The use of emulsifiers allows food manufacturers to reduce the fat content of various food products in a way that allows the emulsion to maintain a nice consistency similar to if the fat hadn’t been removed.

It’s been suggested that the balance of hydrophobic and hydrophilic compounds allows emulsifiers to act as a “zipper” in bringing the oil and water components together.5

Thickening, Binding, and Texturizing

Emulsifiers like carrageenan are used in the above foods to increase their viscosity—foods with high viscosity are thick, while foods with a low viscosity are thin.

Other examples of plant-based food gums used for this purpose include carob bean gum, algin, guar gum, gum arabic, locust bean, gum karaya, and gum tragacanth.6

One sensory property conferred by the higher viscosity is an improved mouthfeel. One reason why fat makes foods so tasty is that it makes foods nice and creamy.

Carrageenan is a common fat replacer used in reduced-fat foods (dressings, baked goods, frozen desserts, cakes, and confections), to provide a creamy mouthfeel.7

The sticky consistency of vegetable gums also makes the additives great for use as binders.8

Carrageenan in Non-Vegan Foods

Just because a food additive is vegan in itself, doesn’t mean that every application of the ingredient will be in vegan-friendly foods.

Meat and Poultry

Manufacturers have long used various food ingredients to produce reduced-fat meat products.

The fat in ground beef is removed and replaced with extenders like carrageenan as well as oat bran or fiber, plant starches, modified food starches, maltodextrins, soy proteins, nonfat dry milk solids, and texturized veggie protein (TVP).9

Some extenders enhance the flavor along with providing a lower the fat content.10

Both meat and poultry products make heavy use of carrageenan as a binder.11

Any kind of mechanically separated and glued together meat needs some sort of binder, and carrageenan is a common one.

The texture of poultry products is determined by a number of factors. The physical removal of the meat from the bone causes the collagen fibers and myofibril proteins to be redistributed, which creates a more stable meat emulsion.12

Another primary factor influencing the texture of meat is the use of vegetable gums like carrageenan.

Carrageenan is also used as a natural curing agent. “Natural” additives are often used to replace chemical additives, for labeling purposes.

While the USDA doesn’t recognize “natural curing”, manufacturers have long used natural compounds like plant gums to cure meats.13

Examples of natural additives used as curing agents include carrageenan as well as vegetable and fruit juices, sodium bicarbonate (baking soda), vinegar, sugar, honey, spices, and food starter cultures.11

Dairy Products

Carrageenan tends to be used in various dairy products for its thickening and stabilizing properties.

For example, chocolate milk requires a stabilizer to help prevent the cocoa solids from settling out of the milk.14

One of the most common stabilizers used for this purpose is kappa II carrageenan (at 0.02–0.03%) because it undergoes a reaction with the milk proteins producing a gel, which gives the chocolate milk a thicker mouthfeel compared to regular milk.15

Sour cream is another common food product you’ll find carrageenan in. To produce a sour cream that’s on the thicker side, manufacturers commonly use MSNF (milk solids non-fat), enzymes, and certain vegetable gums like carrageenan.16

Vegan ice creams are not the only ice-creams that make use of carrageenan and other vegetable gums.

These gums add body to the end product and help stabilize it during the freezing and thawing process.

If you’ve ever had homemade ice cream, you’ve no doubt noticed that it has a much less creamy texture and body compared to commercial ice cream.

This is because commercial ice cream adds stabilizers at about 0.5%. Common vegetable gums include carrageenan as well as sodium carboxymethylcellulose (CMC), agar, guar gum, acacia, alginate, karaya, furcelleran, locust bean, xanthan, tragacanth, and gelatin.17

The gums are also used to help resist melting, improve viscosity, and reduce ice crystal formation.18

The gums serve as stabilizers by attaching to water molecules as they are freed from the melting ice during bouts of increased temperature, such as when opening the freezer door.

The water, being bound to the gums, can’t attach to existing ice crystals. If not for the presence of gum additives, the crystals would get larger and larger over time, which adversely affects the quality.19

The use of stabilizers also makes the production of frozen desserts more economical, because they reduce the amount of cream needed to maintain the body, which lowers production cost.20

Anyway, that’s it for carrageenan. Thanks for reading.

You may also want to check out the following related articles:

- Is Maltodextrin Vegan?

- Is Guar Gum Really Vegan?

- Is Cellulose Gum Vegan?

- Is DATEM Really Vegan?

- Is Soy Vegan? (Soy, Tofu, Soy Milk, Miso, Etc.)

References

- Carrageenan. https://en.wikipedia.org/wiki/Carrageenan

- Understanding Food: Principles and Preparation (Page 44). Amy Brown – Wadsworth Cengage Learning – 2011

- Arendt EK, A Morrissey, MM Moore, and F Dal Bello. Gluten-free breads. In EK Arendt and F Dal Bello F. Gluten-free Cereal Products and Beverages. Elsevier, 2008.

- Understanding Food: Principles and Preparation (Page 420). Amy Brown – Wadsworth Cengage Learning – 2011

- Boyle E, and JB German. Monoglycerides in membrane systems. Critical Reviews in Food Science and Nutrition 36(8):785–805, 1996.

- Understanding Food: Principles and Preparation (Page 271). Amy Brown – Wadsworth Cengage Learning – 2011

- Understanding Food: Principles and Preparation (Page 57). Amy Brown – Wadsworth Cengage Learning – 2011

- Understanding Food: Principles and Preparation (Page 45). Amy Brown – Wadsworth Cengage Learning – 2011

- DeFreitas Z, et al. Carrageenan effects on salt-soluble meat proteins in model systems. Journal of Food Science 62(3):539–543, 1997.

- Understanding Food: Principles and Preparation (Page 153). Amy Brown – Wadsworth Cengage Learning – 2011

- Understanding Food: Principles and Preparation (Page 158). Amy Brown – Wadsworth Cengage Learning – 2011

- Tanaka MCY, and M Shimokomaki. Collagen types in mechanically deboned chicken meat. Journal of Food Biochemistry 20:215–225, 1996.

- Bacus JN. Navigating the processed meats labeling maze. Food Technology 61(11):28–32, 2007.

- Aryana KJ. Flavored milks. In Hui Y, et al., Handbook of Food Products Manufacturing: Health, Meat, Poultry, Seafood, and Vegetables. John Wiley and Sons, 2007.

- Understanding Food: Principles and Preparation (Page 217). Amy Brown – Wadsworth Cengage Learning – 2011

- Understanding Food: Principles and Preparation (Page 223). Amy Brown – Wadsworth Cengage Learning – 2011

- Whistler RL, and JN BeMiller. Carbohydrate Chemistry for Food Scientists. Eagen Press, 1997.

- Martin DR, et al. Diff usion of aqueous sugar solutions as aff ected by locust bean gum studied by NMR. Journal of Food Science 64(1):46–69, 1999.

- Sutton RL, and J Wilcox. Recrystallization in model ice cream solutions as aff ected by stabilizer concentration. Journal of Food Science 63(1): 9–11, 1998.

- Understanding Food: Principles and Preparation (Page 540). Amy Brown – Wadsworth Cengage Learning – 2011